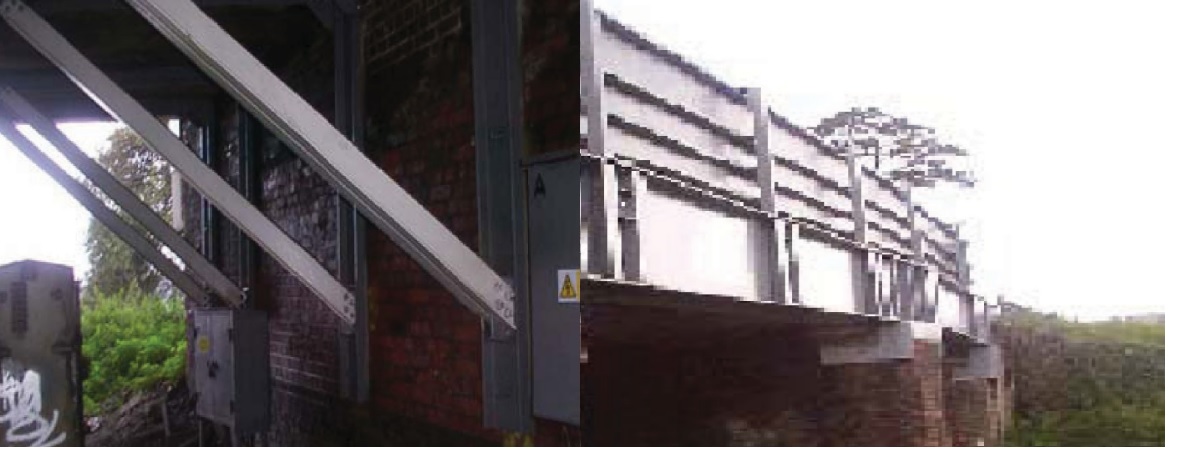

Case Study: CC037: Polyglass for bridges

Winter maintenance for Railway Bridge.

Customer

Structural industry.

Application Date

February 2001.

Scope Of Work

Assess work required on severely corroded railway bridge. Refurbish, maintain and protect Railway Bridge back to safe working condition.

Products

Substrate

Mild steel.

Coating system

•Grit blasted to SIS 05 5900, SA 21/2 (Relate to Corrocoat data sheet SP1, 6/30).

•Zipcoat applied by airless spray, minimum film thickness 850μm (Refer to Corrocoat data sheets 6/20).

•Finally, the externals of the caissons were given a topcoat of Corrocoat Biofoul at 350 microns to provide long-term non-toxic anti-fouling protection in this arduous marine environment.

Due to the extensive worldwide coverage offered by Corrocoat, after delivery Corrocoat’s South African operation were able to mobilize to site to fully protect the internal and external field joints after welding.

Results & Benefits

A spokesman said: “We identified the Corrocoat proposal as being the best solution and this has proved to be true. By using a sister company in South Africa and the same materials applied by Corrocoat’s trained applicators, we were given a single– source guarantee. The same high quality factory standards we enjoyed in the US were maintained in South Africa.”

Credentials

As one of the world’s leading names in anti-corrosion technology, Corrocoat have a proven 40 year track record of providing cost effective long-term corrosion protection to the international oil and gas industry. Offering professional high quality service, both in house and on site, Corrocoat is justifiably proud of the many caissons, pipes and manifolds protected, many of which remain in service after more than 20 years,