Renewables

Renewable energy is growing fast. Given the finite amount of resources we all have available to us, Corrocoat is proud to support this industry.

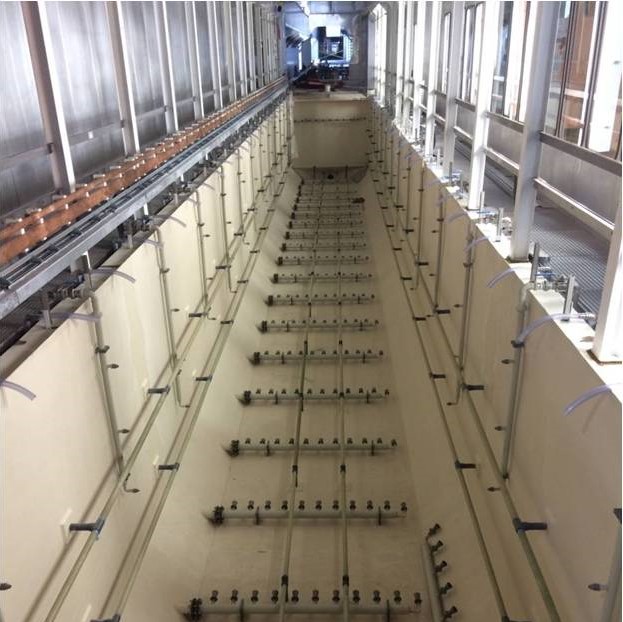

We help with long-term corrosion protection. Our glass flake coatings are designed for preventative maintenance and are particularly effective in sea water environments.

Whether it’s for wave, tidal or wind energy markets, we offer a full collaborative service to companies. From design stage to application of our anti-corrosion coatings, we can provide the protection that keep commercial devices working and reduce the chance of costly shutdowns.

Typical renewable components we coat and treat include:

- Wind and wave devices

- Blades

- Turbine towers

- Biomass plants

- Jackets

- Bio diesel plants

- Monopoles

Renewables Case Studies

CC009: PLASMET HTE USED IN THE REFURBISHMENT OF A VOLUTE PUMP CASING

Corrocoat coatings were used in the recent refurbishment and coating of a volute pump casing for a leader in the forest-based bio-industry. The desired outcome being excellent abrasive resistance.

Click to read more.