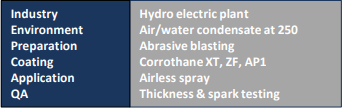

US113: Air & Water Condensate

pumped-storage hydroelectric power station

required refurbishment work and protective

coating . The components are subject to air/water

condensate at temperatures up to 2500F in service.

Solution

The internal surface of the separator tank and anti

surge tank, as well as various pipe spools were

abrasive blasted SSPC SP10, near white blast, to

achieve the required surface profile. External

surfaces were prepared to SSPC SP6, commercial

blast. A final blow down and vacuum clean was

completed to remove all dust before coating.

Corrothane XT was then applied to the internals

to 50 mills dft, CXT provides good chemical and

high temperature resistance in either immersed or

non-immersed service. After suitable curing the

Corrocoat’s team carried out spark testing to

identify any pinholes/holidays to ensure the

integrity of the finished coating. Externally 2 coats

of Plasmet ZF were applied.

On completion of all works, the tanks and parts

were prepared and packaged for transportation

back to the power station and subsequent reinstallation in service.

Quick Check Data