Featured Products

Polyglass VEF

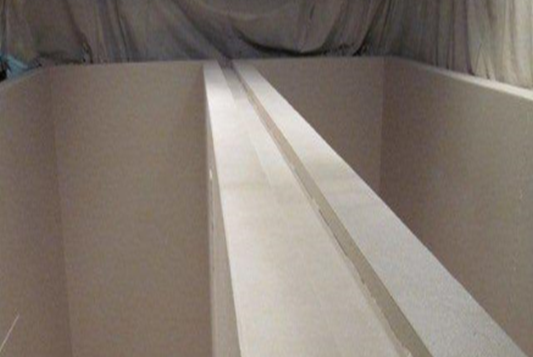

Probably our most frequently specified lining system, Polyglass VEF offers long term corrosion resistance against a wide range of service environments, including over 1,200 chemicals, pH 1-13 at temperatures up to 230֯F (110֯C) in immersion service and up to 329֯F (165֯C) in non-immersion service.

Many coating applicators and contractors prefer to use Polyglass VEF for tank lining projects as it is specifically engineered to hang vertically on a surface when sprayed at thickness of 40 mils dft in a single coat. In addition, we are able to offer the same or superior protection using our systems versus our competitors using a thinner lining system (40-60 mils dft versus 120-150 mils dft) by the utilization of thinner, more consistent, high aspect ECR glassflake, effectively formulated to produce optimal moisture vapor transmission resistance. This allows a contractor to line a given tank faster and using less material than some of the older iterations of glass flake vinyl ester linings that are still offered by many of our competitors.

Generically, Polyglass VEF is a Novalac Vinyl Ester resin based, glass flake reinforced lining system. As do most Corrocoat linings, the combination of the utilization of advanced ECR glass flake and a “secret sauce” of other pigments and additives make this system the best available of it’s kind in the market.

Note that Polyglass VEF is often used in conjuction with the following Corrocoat coatings, each specifically engineered to suit given commonly encountered project requirements:

Polyglass VEHA—For stripe coating of welds and brush application at nozzles, manways, 90’s and knife edges.

Corrofill VE—For filling of pits using a scraper, trowel or equal.

Polyglass PPV – For use to apply fiberglass laminate at high stress areas and at the tank floor-wall interface

Polyglass VEFWR – A highly wear resistant topcoat, applied in service environments that experience high wear, abrasion and erosion

Polyglass VEF is often used in the following service environments:

- FGD Outlet Duct, Module Cap and Recycle Tank Lining

- Lime Storage Tanks

- Neutralization Tank Linings

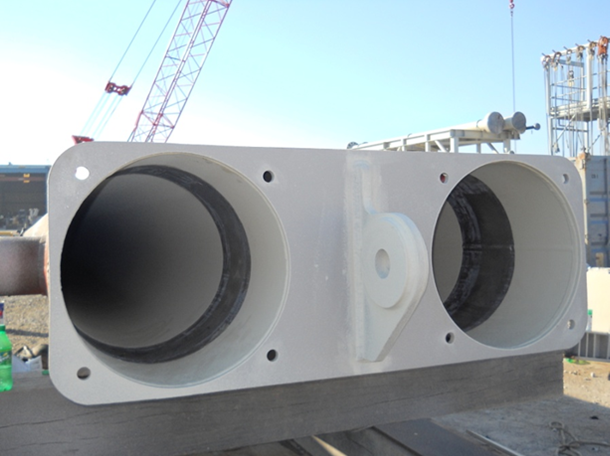

- (Salt Water) Cooling Water pipes, pumps, waterboxes and tubesheet faces

- Hydrochloric Acid (HCl) Loading Pad and Secondary Containments

- Hot Well Can Lining

- Tall Oil Plant Concrete Lining

- Deionized Water U Drain Lining

- Oil-Gas Separator Lining

- Methanol Tank Lining

- Terpine Resins Separator Lining

- Aluminum Chloride Baghouse Lining

- Electrochemical Dip Tank Lining

- Produced Water Pipe Spool lining

- Water Injection Pipe Spool Lining

- Internal Lining for Prover Loops

- Fire Water Caissions