Featured Products

Plasmet AR3

Plasmet AR3 is proprietary blended epoxy lining specifically formulated to provide long term immersion to 98% Sulfuric Acid.

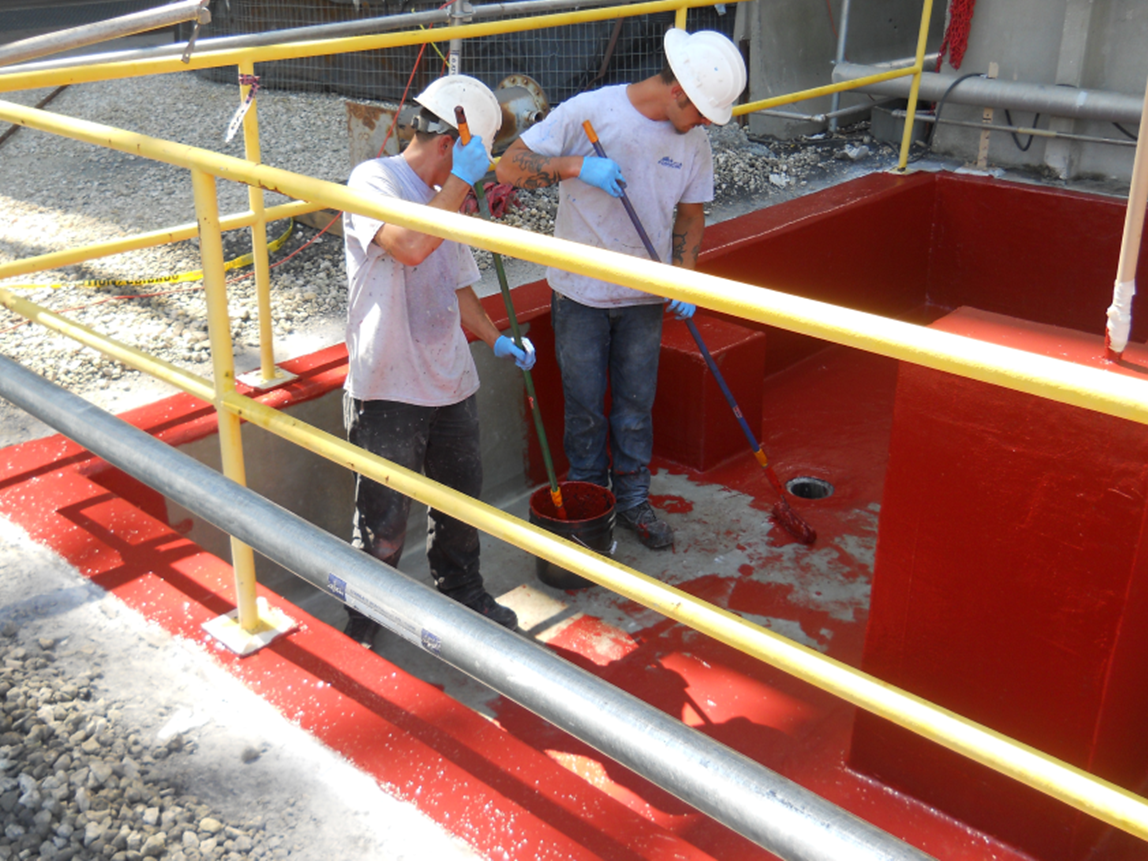

Where concrete is left unprotected from residual aid runoff, it may be consumed as the result of a chemical reaction with the concrete, which has a high pH of 10 with the sulfuric acid, pH of less than 1. Common applications include lining or coating concrete pump bases and sulfuric acid secondary containments. A Before and After of a pump base follows.

Note that the above lining at the pump base has lasted 10 years and counting. During surface preparation, it was found that as much as 3 inches of the existing concrete had turned to “mush.” Once cleaned, we primed the remaining concrete with Plasmet ECP (Epoxy Concrete Primer) and then mixed and poured our Corrocoat Epoxy Polymer Concrete (EPC) .

In addition, many customers in Florida whom are required to use a sulfuric acid resistant liner approved by the FDEP, choose Plasmet AR3 to line their new and existing secondary containments.

Applied with a brush or roller in 3 successive coats to achieve 48—60 mils dft. As the material sets up within an hour, most crews can apply all three coats to a sulfuric acid secondary containment in a single day.

Plasmet AR3 is also applied to structural steel, which may be affected by runoff from a pump or valve leak above or adjacent to the acid.

In many areas within a heavy industrial plant that may have structural steel that is affected by sulfuric acid it may not be feasible to carry out extensive surface preparation, hot work or abrasive blasting. In this case, we typically specify a system that is primed with Plasmet ZF or Plasmet ZGalv (specifically suited for galvanized steel) as a surface tolerant primer, which crosslinks with the Plasmet AR3 to provide a surface tolerant, 98% sulfuric acid resistant coating.

Note that Plasmet AR3 is a stock product at Corrocoat USA, manufactured and supplied out of our Jacksonville, Florida location.