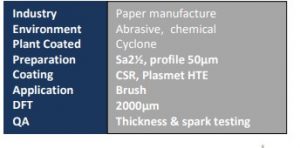

Protection from Abrasion

A pressure cyclone is designed to separate

steam from the pulp in a paper or card

manufacturing plant. The pulp itself coupled

with high temperatures and chemical content

produces a very aggressive corrosive and

abrasive environment.

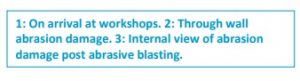

Two cyclones were delivered to Corroserve’s

workshop in Leeds in need of a programme of

repair and onward protection against abrasion.

Both cyclones were suffering from severe

abrasion damage and both exhibited through

wall defects.

The paper plant operators wanted to protect

against future damage, and the resulting

expensive downtime, and a significant increase

in service lifetime was also required.

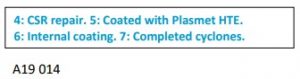

Corroserve recommended that after being

abrasive blasted to Sa2½ the internal surface

be repaired and reinforced using wetted out

300gsm glass fibre matting. After initial cure

multiple coats of Plasmet HTE were applied to

both internal and external surfaces to reach a

required DFT of 2000 microns.

Plasmet HTE

cured epoxy, containing both stainless steel

flakes, glass flakes and silicon carbide. The

specialist coating provides excellent abrasion

(and chemical) resistance.

CSR and HTE

cyclones, chemical process vessels, sugar beet

pulping drums etc. It is also useful for building

up damaged areas of pump impellers and

casings where impact or abrasion, are

prevalent. The coating has good temperature

resistance; Immersed conditions – 275°F. Nonimmersed conditions – 338°F.

Plasmet HTE in conjunction with composite

structural repair techniques will ensure the

cyclones will have an increased service life and

much greater protection against abrasion.