Case Study: CC019: Brake cylinder repair

Client

Rail industry.

Application Date

March 2004.

Scope Of Work

Machine, coat and post machine brake cylinder bore to return to correct bore diameter and surface finish.

Products

Substrate

Carbon steel.

Coating system

• Pre-machined cylinder bore to Ø357.15

• Grit blast internally to ISO 8501-1 cleanliness

standard SA 21/2 with a minimum surface area

of 50µm.

• Applied Polyglass VEF (with 5% styrene) by rolling

• Assemble valve

• Post-machined to Ø356.1 (+0-0.2)

• Thickness checked and spark tested at 6.5kv

• Grit blast internally to ISO 8501-1 cleanliness

standard SA 21/2 with a minimum surface area

of 50µm.

• Applied Polyglass VEF (with 5% styrene) by rolling

• Assemble valve

• Post-machined to Ø356.1 (+0-0.2)

• Thickness checked and spark tested at 6.5kv

Coating credentials

Corrocoat has completed several similar jobs since

October 1996 utilizing its Polyglass VEF coating, which

offers superior corrosion resistance, thereby prolonging the service life of these brake cylinders with the added benefit of reduced maintenance costs.

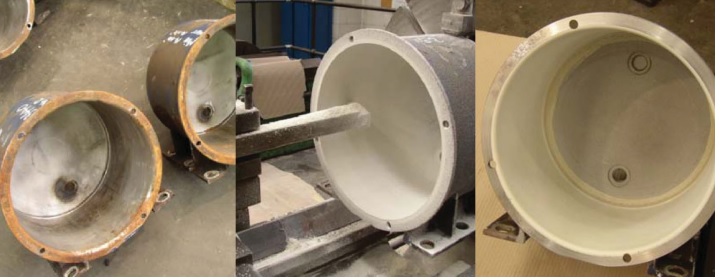

Photographs

Left: Brake cylinders on arrival in our works.

Middle: Brake cylinder during post-machining.

Right: Brake cylinder on completion.

Middle: Brake cylinder during post-machining.

Right: Brake cylinder on completion.