US124: Refurbishment of Chemicals Vessel and Lid

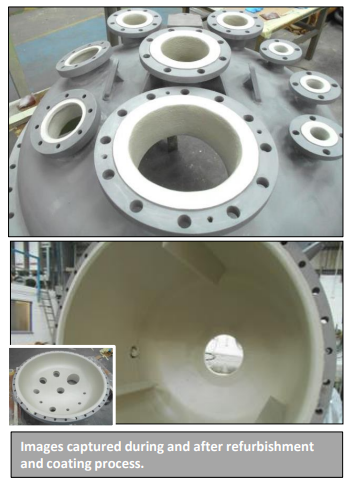

A chemicals processing vessel and lid used in the

manufacture of potassium bromate required a

programme of refurbishment and lining with a

suitable protective coating. The lid of the vessel

had 10 access/sampling ports that all required

preparation and coating.

As a first step the vessel and lid were abrasive

blasted, both internally and externally, to achieve

the required cleanliness standard before being

thoroughly cleaned down to remove all dust and

debris.

Polyglass VEF was applied to a DFT of 750µm,

VEF is formulated for immersed environments

where superior resistance to chemical attack is

required within the full pH range.

In order to provide advanced protection from

abrasion a second coat of Armagel was applied.

The externals of the vessel and lid were coated

with Plasmet ZF to ensure all round corrosion

protection. A full quality assurance inspection

was conducted including DFT and spark testing

to ensure the quality of the work.

The application of specialist protective coatings

will significantly increase the expected service

life of the chemicals vessel.

Quick Check Data