The Industry

The Challenge

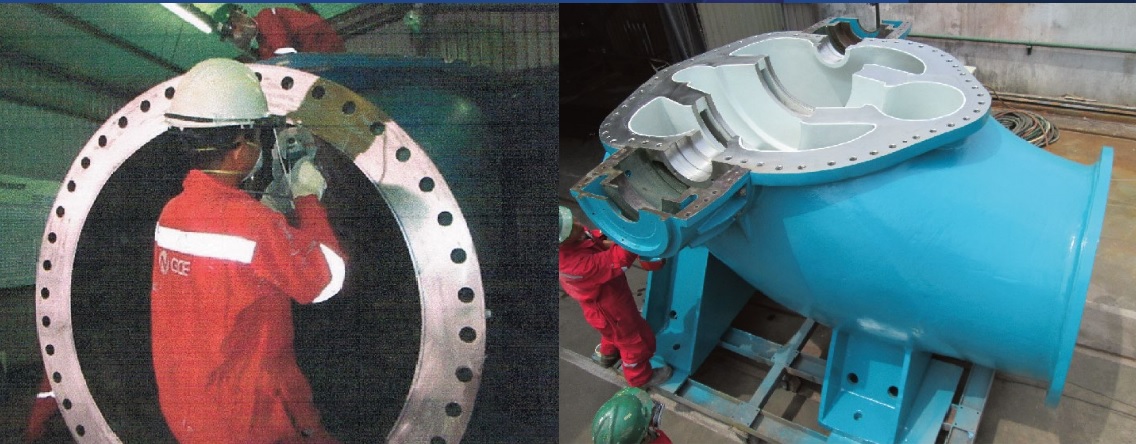

Corrocoat Licensed Applicator, Vietnam Glo Coating Engineering JSC (VGCE) was contacted by PetroVietnam Ca Mau Fertilizer JSC, as their engineers were concerned over the condition of one of their pumps. The pump is used in the production of nitrogenous fertilizers and was handling abrasive and corrosive chemicals.

The Solution

GCE engineers recommended a surface preparation, engineering and coating package that would protect the pump casing and impellor comprising:

• High pressure wash with detergent to remove dirt and oil

• Rebate the flanges on the pump housing (7mm wide x 1.5mm deep)

• All surfaces to be shot blasted to remove contaminants and achieve a surface profile of 75 µm. to allow the subsequent coatings to bond successfully and guarantee their longevity.

• For the pump internals and impellor a coat of Corroglass 632, followed by Corrofil VE (to fill holes), Corroglass 602 and finally Corroglass 652 applied to achieve a total

thickness of 1800 µm. This coating combination was recommended as it combined excellent abrasion and

corrosion resistance and was therefore an effective and long term solution.

• The pump casing external surfaces to be coated with Plasmet ZF at 250 µm, the pump housing flange faces rebated and the impellor balanced.

Results & Benefits

Credentials

Corrocoat has 40 years’ experience in offering corrosion management coatings to chemical plants. In particular, the glass flake coatings are ideally suited to this field, offering superb chemical, temperature and erosion resistance. Corrocoat has proven to be a reliable partner, having completed a wide range of projects, including treating: Pipework, Pumps, Valves, Structural steelwork, Process vessels, Storage tanks and Concrete bunds.

Right: Final inspection before returning pump to customer