Case Study: CC018: Fluid efficient coating of a pump casing

Fluiglide treatment of the internal surfaces of a 14/12 hsc pump.

Client

Major pump manufacturer.

Application Date

October 2007.

Scope Of Work

Chamfer split faces and flanges and prepare casing

ring lands.

Blast and coat internally with fluid efficient coating.

Cast in ring lands.

ring lands.

Blast and coat internally with fluid efficient coating.

Cast in ring lands.

Products

Internal Coating system

Grit blasted internally to ISO 8501 – Cleanliness

Standard SA 21/2.

Coated internally using Corroglass 600 Series to a

minimum 750 DFT.

Thickness checked.

Spark tested at 9.5 Kv.

Single coat of Fluiglide applied.

Standard SA 21/2.

Coated internally using Corroglass 600 Series to a

minimum 750 DFT.

Thickness checked.

Spark tested at 9.5 Kv.

Single coat of Fluiglide applied.

External coating system

Grit blasted externally to ISO 8501-1 – Cleanliness

Standard SA 2 and applied one coat of Plasmet ZF

Standard SA 2 and applied one coat of Plasmet ZF

Coating credentials

Fluiglide has been applied to thousands of pumps

worldwide, achieving significant improvements in

efficiency.

Fluiglide offers both increased efficiency levels and an

effective corrosion barrier. Typical efficiency

improvements of 4-6% are achieved using Fluiglide

(subject to design and operational parameters.

worldwide, achieving significant improvements in

efficiency.

Fluiglide offers both increased efficiency levels and an

effective corrosion barrier. Typical efficiency

improvements of 4-6% are achieved using Fluiglide

(subject to design and operational parameters.

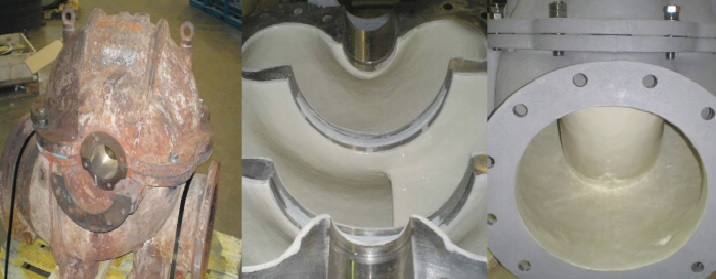

Photographs

Left: Pump casing as received.

Middle: Internals coated prior to ring land casting.

Right: Pump fully re-furbished.

Middle: Internals coated prior to ring land casting.

Right: Pump fully re-furbished.