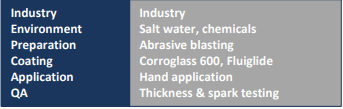

Problem

An HSC pump required a programme of

refurbishment, the client had asked Corrocoat to

recommend a coating that could improve the

efficiency of the pump in operation.

Solution

Corrocoat recommended applying Fluigide to the

wetted surfaces. Fluiglide’s sole purpose is to

reduce fluid friction, increasing flow in the

boundary layer, thus reducing power requirements

and giving better efficiency. This applies both for

the reduction of losses in transmitting fluids

through pipe work and channels, and increasing

the efficiency of fluid prime movers.

The pump was abrasive blasted to achieve the

required surface profile after which multiple coats

of Corroglass 600 were applied to provide

resistance to solvents and acids.

After curing Fluiglide was applied to a thickness of

500µm. Fluiglide is a hydrophobic coating

designed to reduce fluid friction thus improving

flow and efficiency.

Corrocoat combines mechanical engineering with

advanced coatings systems that allow even

severely damaged pumps to be refurbished at a

fraction of the cost of replacement.

Quick Check Data