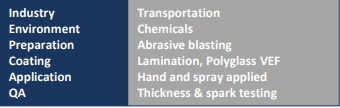

Steel ISO Tank

An ISO tank used to transport chemicals required a

programme of refurbishment and the application of a

protective coating system to extend its service life.

Solution

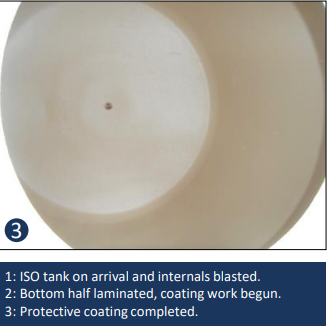

The internal surface was blasted to achieve a surface

profile of 50µm. All edges/corners were hand striped

with Polyglass VEF, before a first coat of VEF to a wft of

750µm was applied by airless spray.

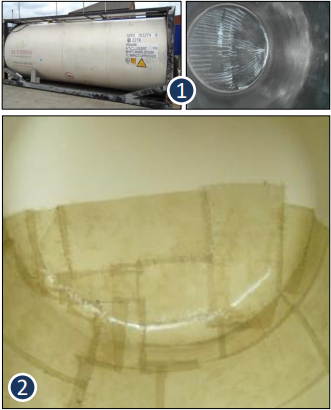

The bottom half of the tank was laminated with wetted

out multi-axial glass fabric to improve the integrity of the coating and avert cracking/de-lamination of the final coating. After suitable curing a second coat of Polyglass VEF was applied to a wft of 750µm, spark testing was completed to identify any pin holes/holidays.

A final coat of Polyglass VE veilcoat was applied to a

required dft of 200µm to complete the coating solution. Polyglass VEF is a ester/acrylic co-polymer loaded with glass flake and is ideal for use in areas were aggressive chemical conditions are experienced. It is also used in aggressive atmospheric or spillage conditions (bund areas) and potable water applications.

On competition of the lamination and coatings work the tank was filled with water to test the integrity of the coating system under stress.

Finally the ISO tank was dispatched to the client fully

protected against chemical corrosion.

Quick Check Data