Case Study: US104: Kaolin Sand Slurry Grinder Tank and Blades

Internal lining of grinder tank.

Mixer blades coated with Plasmet HTE for abrasion protection.

Problem

A rubber lining used to protect the blades of a Kaolin sand slurry grinder would delaminate from the blades once or twice a year introducing rubber that caused damage to downstream pumps. The client wanted a protective coating that would significantly extend the expected service life of the blades. Additional protection was also sought for internals of the grinder tank in which the blades are located and rotate.

Solution

Corrocoat applied Polyglass VEF/VEF WR to the tank to

provide a barrier lining with a wear resistant topcoat

and Plasmet HTE to the blades. The HTE was applied in

different colors to make it easy to visually determine

how much of the protective coating was left.

This system increased the previous 6-9 month lifecycle

to 32-36 months while eliminating the damage caused

after rubber delamination. The solution also meant a

significant reduction in downtime and associated cost

for the client.

Conclusion

Corrocoat’s ability to engineer a repair, manufacture

the required materials, and carryout the application

allowed for a quick and permanent repair. Corrocoat’s

sole-sourced solution reduces project lead time while

eliminating opportunity for misunderstandings or

conflicting interests between different firms.

the required materials, and carryout the application

allowed for a quick and permanent repair. Corrocoat’s

sole-sourced solution reduces project lead time while

eliminating opportunity for misunderstandings or

conflicting interests between different firms.

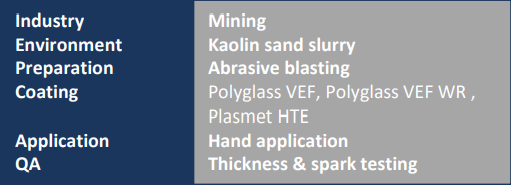

Quick Check Data