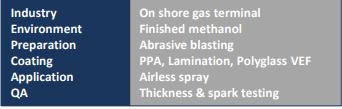

US115: Finished Methanol Storage Tank

storage tank at an onshore facility had found

corrosion issues both internally and externally.

Solution

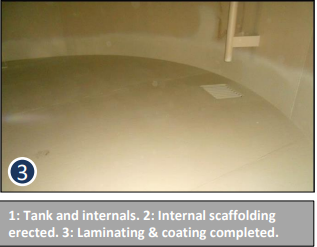

Corrocoat proposed a program of work for the

surface preparation and application of specialist

protective coatings (Polyglass PPA and VEF), for the

internals, to the base and 4 strakes up the wall.

The client also requested that the roof was to be

abrasive blasted to remove any surface residue.

An inspection report of the methanol tank (28ft

diameter x 31ft high) stated pitting with a

maximum depth of 160mils was found on the

internal base and shell, a suitable filler material

should be utilized in these areas.

The project involved mobilizing Corrocoat

technicians for a period of 18 days to work on site.

The technicians had to deploy all site equipment

including environmental control equipment. A feat

of organization and coordination that Corrocoat’s

on-site teams are well versed in.

Refurbishing and lining the internals of the tank

with Polyglass VEF will protect against corrosion

and reduce maintenance and down time costs.

Quick Check Data