US117: Abrasion Damage

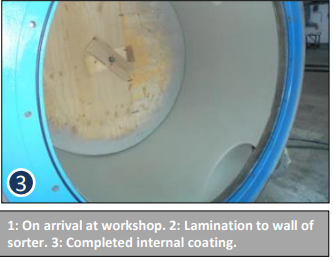

A pair of stainless steel fibre sorters were suffering

heavy wear and abrasion damage to the inner

stainless steel surfaces of the unit, the plant

operator approached Corrocoat to suggest a

solution. Corrocoat was informed that one unit

had a previous ceramic tile repair that had failed

and needed replacing.

Solution

To begin with the failed repair was removed and

the internal surfaces of the fibre sorters were

blasted to SSPC SP10, near white blast, to give a

minimum profile of 2 mil. The Corrocoat team

laminated the surface with multi-axial glass fabric

thoroughly wetted with laminate resin and

rollered to remove any air pockets.

After drying Plasmet HTE was applied as a

protective lining by airless spray to a minimum dry

film thickness of 80mil. Plasmet HTE is suitable for

substrates where abrasion and corrosion

resistance is required. A dft of 120mil was

required at the critical point where the fibre

enters the sorter around the feed pipe.

On completion of the repair and coating work the

units were packed for transportation back to the

paper manufacturing plant.

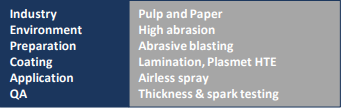

Quick Check Data