Case Study: CC035: Polyglass VEF for prover loops

Prover loop protection

Client

Oil & gas industry.

Application Date

August 2003.

Scope Of Work

For the prover loop to be accurate in measuring the flow of crude oil, it is essential that the lining is protected from corrosive properties found in such liquids. Therefore the loop had to be coated with a product that was able to withstand everyday usage.

Products

Substrate

Carbon steel.

Coating system

The surface was then blasted to a cleanliness standard of ISO 8501-1 cleanliness standard SA 21/2. With a minimum surface profile of 50 microns. One coat of Corrocoat’s Polyglass VEF was then applied using Agmec’s airless spray pump. A layer of Fluiglide VE was then applied to the inside surface of the pipe, using the airless spray application utilizing the Agmec Internal pipe spraymachine.

Coating credentials

The whole of Corrocoat’s Polyglass range has proven highly effective in extremely corrosive environments. Polyglass offers a remarkably low permeation rate, combined with excellent resistance to abrasion and cathodic disbondment. The system provides an effective, long term corrosion barrier, preventing reductions in performance due to surface corrosion.

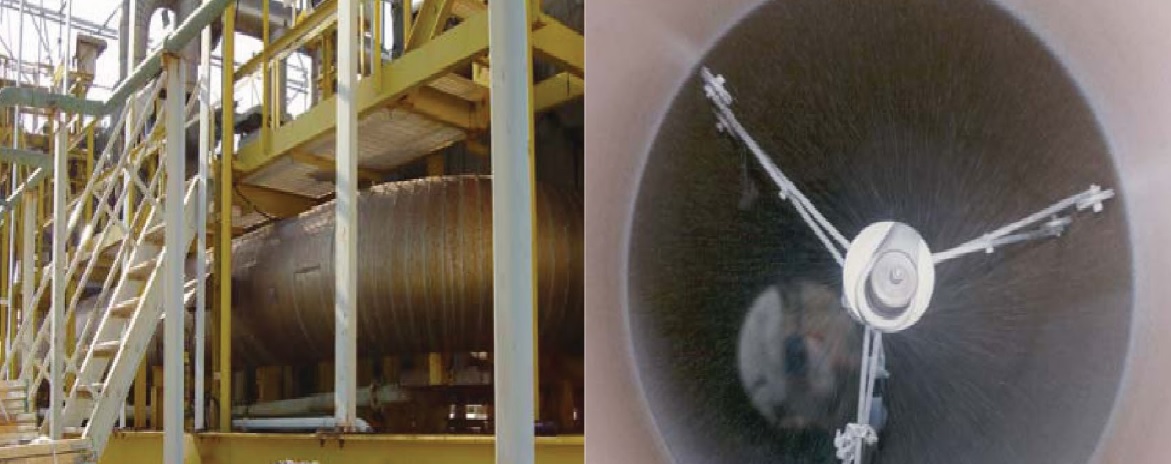

Photographs

Left: A prover loop system.

Right: Agmec internal pipe spray machine.