Problem

A cooler water box cover has suffered serious corrosion damage to a point where it would be considered beyond repair for most companies, without the established refurbishment expertise of Corrocoat.

Corrocoat advised the client that the cover could be

refurbished and returned to service a cost substantially lower than replacing the damaged cover.

Cracking of the mild steel cover was stabilized by

performing external metal stitch repairs. The internals were then re-profiled, followed by blasting and coating using a high build vinyl ester coating. Corroglass 600 provides resistance to cavitation, erosion and impact whilst in operation under adverse conditions.

Solution

• Remove existing coating. Pre machine rebates. Grit

blast internals to ISO 8501-1, SA2½. Carry out metal

stitch repair.

• Coat using Corroglass 600 to a minimum dft of

1.5mm. Post machine. Grit blast externals to ISO

8501-1, SA2½.

• Apply Plasmet ZF followed by a proprietary topcoat.

Conclusion

Corrocoat has a proven track record working in sea

water environments. The customer needed a quick

turn round to minimise downtime, and Corrocoat was

able to meet these requirements, alongside a

projected design life of 18-20 years.

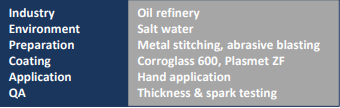

Quick Check Data