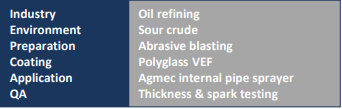

Scraper Trap

A newly fabricated 8/10” scraper trap required

specialist protection against corrosion before entering

service. The trap was due to be installed at an oil

refinery and would experience constant exposure to

sour crude oil.

The internals of the scraper trap were abrasive blasted

to achieve the required cleanliness standard of SSPC

SP10, near white blast, before being thoroughly

cleaned down and vacuumed to removed all dust and

debris before coating work could begin.

Polyglass VEF was then applied, using Agmec internal

pipe spraying equipment, to the required DFT of 50

mils. Polyglass VEF is ideal in immersed environments

where superior resistance to chemical attack is

required within the full pH range. The coating also

benefits from having Lloyds register approval.

Post curing, thickness and spark testing was conducted to ensure the quality of the finished coating. At the same time a thorough visual inspection was completed as further quality assurance. The externals of the scraper were blasted to SSPC SP6, commercial blast, after which a primer and an epoxy top coat were applied.

On completion of the coating work the door was post

machined to specified tolerances, after which the trap

was prepared for dispatch and subsequent installation.

Quick Check Data