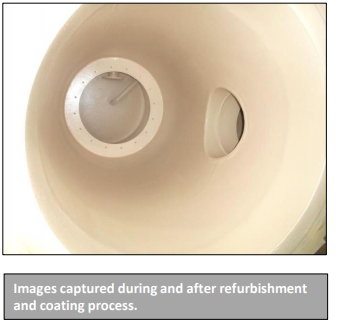

US123: Seawater Filtration Vessel

A coarse seawater filtration vessel required

protection against constant exposure to corrosive

seawater when in service on an offshore oil platform.

Corrocoat had coated a sister vessel 2 years

previously and the client was so impressed with it’s

performance in service that they specified the same

level of protection for this vessel.

The filtration vessel was delivered to the company’s

workshop where the first task was to abrasive blast

the unit to achieve the required cleanliness standard.

After a thorough clean down and vacuum to remove

all dust and debris all the internal joints were stripe

coated with Corroglass 600. A first coat of Polyglass

VEF, which provides resistance to seawater as well

as many chemicals and solvents, was then applied.

After curing a second coat of VEF was applied by

airless spray, the reach the specified DFT of 60mils.

The external surfaces of the vessel and lid was coated

with Plasmet ZF, a surface tolerant coating. Finally a

second coat of Corrocoat ZIP E, which gives good

protection in aggressive atmospheric environments

was applied.

After curing the vessel was thickness and spark

tested to identify any holidays, none were present,

and ensure the professional quality of the coating

work completed.

Quick Check Data