Concrete Cracks & Expansion Joints

THE TREATMENT OF EXPANSION JOINTS OR ACTIVE CRACKS IN CONCRETE SURFACES TO BE OVERCOATING WITH POLYGLASS

Polyglass and Polyglass VE exhibit good characteristics in terms of flexural modulus, however elongation to break is poor being between 0.3 and 1.5% dependent upon coating thickness, state of cure and diffusion condition. It is obvious with this low elongation characteristic that the coating will crack with any relative movement at the expansion joint or crack interface. In order to avoid this taking place methods of treating these areas have been evolved, these are detailed below:

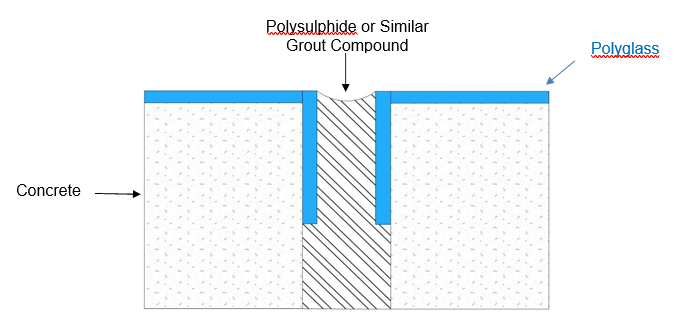

Treatment of Expansion Joint

Grouted expansion joints should have the grouting material removed, the coating should then be applied in accordance with the general procedure and specification to the bottom of the grout recess and on completion of cure the joint should be re- grouted utilizing a suitable grouting material for the service environment. Where such grouting material is not available it may be desirable to treat with one of the alternative methods.

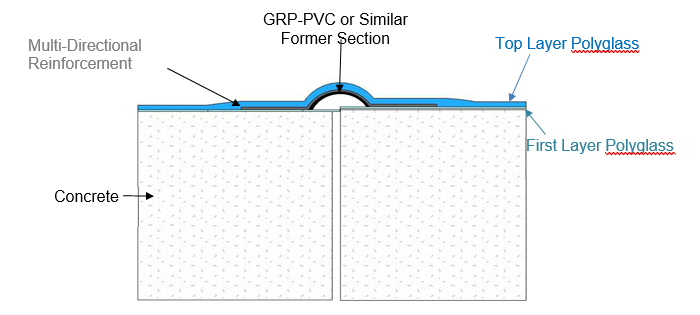

Treatment of Noble Crack

Where joint movement is expected to be severe this can be accommodated by forming a convolute utilizing multi-directional woven reinforcement over the movement area utilizing a suitable former and then overcoating to the usual coating specification ensuring that the thickness does not exceed 2mm.

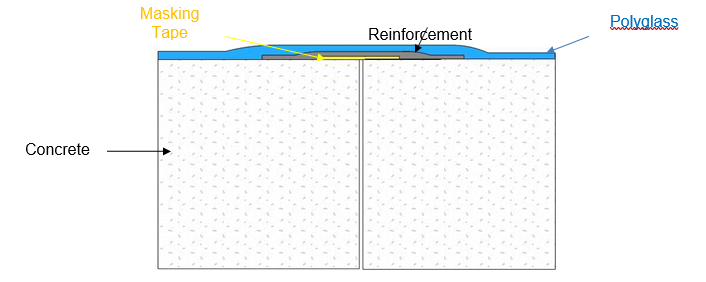

Treatment of Stable Crack

Where joint movement is stable and minor movement due to pressure change has to be accommodated the displacement area should be treated by attaching masking tape to form a no-bond area which is then reinforced utilizing multi-directional fiber reinforcement before overcoating.