PLASMET

Corrothane PA2

Product reference: 5/42

Product title: Corrothane PA2

Valid from: Jan 31, 2020

Last reviewed: Jan. 31, 2020

Type: A high performance polyester-aliphatic urethane topcoat.

Suggested use

A topcoat available in a wide range of colors. Corrothane

PA2 is designed to be used primarily over the top of other

Corrocoat epoxy coatings to give the color required and

excellent color retention and weathering properties.

Designed for use in external service, on new construction

and maintenance work, within many industries including;

marine, offshore structural work, FGD structures, tank,

vessel, pipe externals and many aggressive atmospheric

service environments. Corrothane PA2 has good

resistance to chemical vapors and is splash and spillage

resistance against many dilute acids, solvents and fuels.

Health & safety

Before handling this product the material safety data sheet

should be read and all precautions observed.

Surface preparation

Corrothane PA2 is designed as a top coat for other

Corrocoat products, predominantlyPlasmetZF.Pleaserefer

to the relevant application data sheet for the prime/ build

coat for surface preparation details.

Application equipment

Airless spray,brush or conventional spray.For airless spray

recommended tip size 13-19 thou. Spray pressure 2,400

– 2,900 psi.

Application

Typically applied in 1-2 coats by brush or spray at 2 mils

(50 microns) dft per coat (approximately 3mils (75 microns)

wet film thickness).

Mixing ratio

2:1 base to activator by volume.

Pot life

3 Hours at 68 F

(20°C); 40 min. at

95 F(35°C)

Thinners

Use Corrothane PA2 Thinner. Use less than or equal

to 5% thinner by volume.

Color availability

Most color requests can be accommodated. Price

may vary with color.

Volume solids

70%; may vary by color

Theoretical spreading rate

374 sf per gal per 2 mils (27.4m²/liter at 25 microns) dft (3

mils or 75 microns wft).

(Practical coverage valueswill depend upon environmental/

application conditions, operator technique and geometry of

work. Appropriate loss factors should be taken into account.

Corrocoat accepts no liability for any differences in actual

spreading values obtained. The recommended thickness

testing for the system is SSPC PA2)

Temperature Limits

200 F (93 C) sustained; 235 F (113 C), intermittent exposure

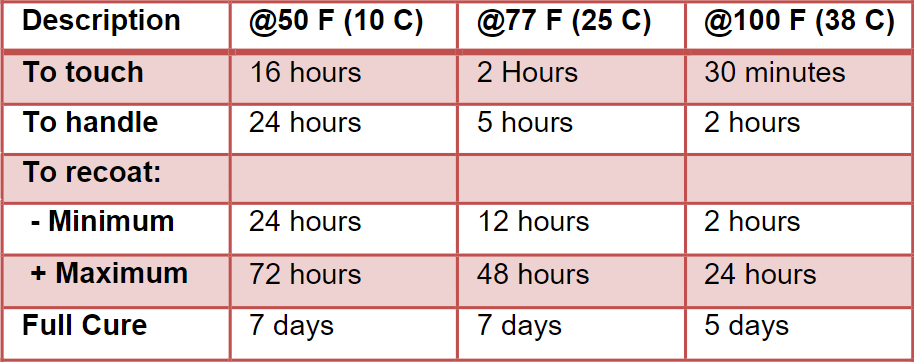

Dry,Handleand Overcoating Times

*All values are approximate. Physical data is based on the product being in good condition before polymerization, correctly catalyzed and full cure being attained. Unless otherwise stated, physical data is based on a test temperature of 68°F (20°C), test results may vary with temperature. Information regarding application of the product is available in the Corrocoat manual. Should further information be required, please consult Corrocoat Technical Services. Do not apply below 40 F (5 C) and above 120 F (49 C). Do not apply if the relative humidity is greater than or equal to 85%.