CORROCOAT

ZIP E SCREED

Product title: ZIP E SCREED

Valid from: May 2019

Last reviewed: September 2020

Type: A three part epoxy glassflake screed, intended for application over Plasmet ECP or Zip-E to restore grade and/or provide a non-slip surface on concrete and metallic surfaces.

Suggested use

Limitations

Health & safety

Surface preparation

Metals: For best results Grit blast to SSPC-SP10 standard and apply over a barrier coat of Zip-E. (For full details refer to Corrocoat Surface Preparation Specification SP1.) Zip E can also be applied to mechanically prepared or water blasted surfaces or where Plasmet ZF has been used as a primer.

Concrete: Remove surface laitance and ensure a mechanical profile via scarification, abrasive blasting of other approved methods as per Corrocoat Surface Preparation sheet SP5. Priming is required, use Plasmet ECP as the primer.

Recommended DFT

Dependent upon intended use, geometry of work and service conditions. Zip E Screed is normally applied to achieve DFT’s of 40 to 1 inch (1,000 to 25,000 microns) by applying at 10% greater WFT’s. Single coat application is preferred but multiple coats may be used to achieve the required DFT, refer to data on overcoating times.

Volume Solids

Practical Coverage Rate

Note

Flash Point

Mixing Ratio

14.3:4.9:10.8 Base to Hardener to Aggregate by weight / weight / weight. (Note: mix base and hardener thoroughly)

Application

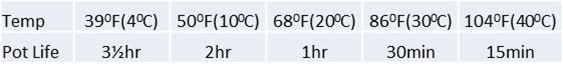

Pot Life

Packaging

Catalyst/Hardener Type

Modified Amine Adduct

Storage Life

Base and Hardener: 12 months in unopened tins, store away from heat sources and direct sunlight.

Color Availability

White and light grey as standard. Other colors available upon request, price of material subject to color and quantity.

Note

Overcoating

Where multiple coats are required, overcoating may take place after 3 hours at 68°F (20°C). The maximum overcoating time is 72 hours at 68°F ( 20°C). Overcoating times will reduce significantly at higher temperatures and/or in strong sunlight. The minimum overcoating time at 50°F (10°C) is 24 hours, refer to Corrocoat Technical Services for overcoating instructions below 50°F(10°C).

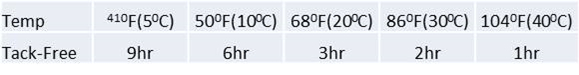

Cure Time

Tack-free in less than 3 ½ hours, full cure 4 days at 68F (20C).