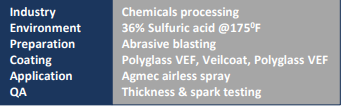

US121: Protection Against Sulfuric Acid

A tank, designed to enter service as an arsenic

scrubber tank would be subject to 36% sulfuric acid

(which would dilute in the scrubber process) at

operating temperatures up to 1750F.

The tank was transported to Corrocoat’s workshop

and was abrasive blasted to SSPC SP10, near white

blast ,the required cleanliness standard. It was then

thoroughly cleaned down and vacuumed to remove

all debris before any coating work could begin.

Polyglass VEF (which has resistance to many

chemicals and solvents) was then applied using

Agmec pipe spraying equipment, to the specified

DFT of 60mils.

All interfaces were then laminated to add strength to

the final coating before a top coat of Polyglass

Veilcoat was applied. The external surfaces were

coated with Plasmet ZF, a surface tolerant coating,

before a final coat of Corrothane AP1 was applied.

After the required curing period the tank was

thickness and spark tested to identify any holidays

(none were present) and ensure the professional

quality of the coating work.

Lining the tank, internally and externally with

specialist protective coatings will significantly

increase the expected service life.

Quick Check Data