Case Study: CC040: Biofoul for inlet screens

Huge savings with over 4 years’ service and virtually no marine growth.

Customer

Marine industry

Application Date

September 1998.

Scope Of Work

Marine growth on sea water intakes causing significant reduction in intake flow. Requirement to cut costs of regular maintenance.

Products

Substrate

Mild steel.

Coating system

• New substrate grit blasted to ISO 8501-1

Cleanliness standard SA 21/2 with a minimum surface

profile of 50µ.

• Whole sample treated with corrosion barrier coating,

Polyglass VEF by airless spray application to achieve a

minimum dft of 900 microns.

• Topcoat of Biofoul applied by airless spray application to achieve a minimum dft of 250 microns

Coating credentials

As an anti-foul, Biofoul provides an excellent alternative to toxic anti-fouling materials, including electrolytic processes, which produce unwanted levels of chlorine which can also cause serious corrosion problems.

Biofoul has been tested in an independent laboratory for both effectiveness and non-toxicity.

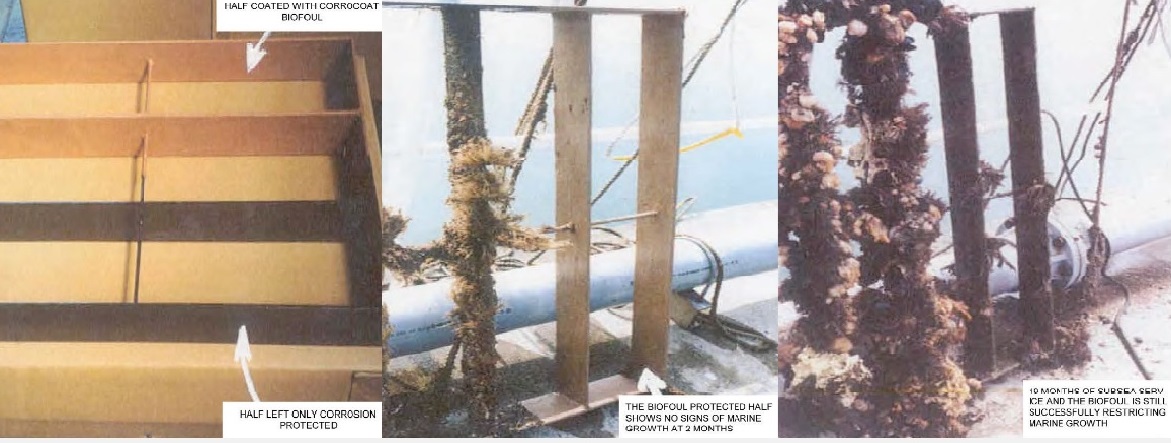

Photographs

Left: Clean sample coated totally with Polyglass

Anti-corrosion coating, and half recoated with a veil of

Biofoul. When first applied, Biofoul is copper/gold in

color. The color changes with age to the pleasantly

green appearance of oxidized copper.

Middle: The sample after just 2 months sub-sea service.

Right: The same sample after 19 months sub-sea service.

Anti-corrosion coating, and half recoated with a veil of

Biofoul. When first applied, Biofoul is copper/gold in

color. The color changes with age to the pleasantly

green appearance of oxidized copper.

Middle: The sample after just 2 months sub-sea service.

Right: The same sample after 19 months sub-sea service.