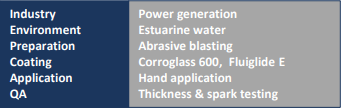

Refurbishment of Butterfly Valves

plant required a programme of refurbishment and

protective coating.

Solution

After the required surface preparation had been

completed the valve body was coated with

multiple coats of Fluiglide E, a coating designed to

offer a smooth uninterrupted surface, increasing

overall efficiency levels whilst affording a degree

of resistance to abrasion.

When cured the seal seat was post machined

and the coating was thickness tested and spark

tested to ensure no holidays were present.

The blade was prepared in the same manner as

the body by grit blasting and was coated with

Corroglass 600 to a dft of 750µm. The blade was

post machined as required and thickness and

spark testing was completed to identify any

holidays and to ensure the quality of the final

coating.

The butterfly valve was then prepared for

transportation and re-installation in the cold

water intake system of a power station.

Quick Check Data