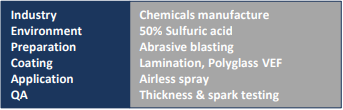

US114: 50% Sulfuric Acid

required protection against chemical attack.

Solution

The following pregame of preparation and coating

works was specified:

• Preparation: abrasive blasting to SSPC SP10, near white blast.

• One coat Polyglass PPA was applied as a holding

primer.

• Multi-axial glass fabric lamination was applied to

the internal interfaces to add strength to the

coating where flexing might occur.

• Polyglass VEF applied by airless spray to achieve

a DFT of 60 mils.

• Spark testing to ensure the coating is free from

holidays/pin holes.

• Polyglass VE Veilcoat was applied as a top coat,

specifically designed for aggressive chemical

environments.

• Post cured at 140-180°F for 8 hours to ensure full

cure prior to entering service.

• Externally 2 coats of Plasmet ZF and a finish coat

of Corrothane AP1.

Polyglass VEF is excellent in immersed conditions

and provides excellent resistance to chemicals,

acids and demineralised water.

Quick Check Data