Case Study: CC024: Fire mains reducing piece

Long term protection against corrosion for fire mains reducing piece

Client

Major refinery

Application Date

March 2007.

Scope Of Work

Protection required from sea water for reducing piece

forming part of a fire mains system. Without

protection, severe corrosion would occur rapidly in this aggressive sea water environment.

Substrate

Carbon steel.

Application method

Grit blast internally and externally to ISO 8501-1 SA 21/2. Corroglass 600 series applied internally to a minimum dft of 1.5mm, carried through into flange rebates and finished flat. 100% spark tested and thickness checked.

Two coats of Plasmet ZF applied externally, Top gloss

coat of Corrothane AP1 (color green 14 e 53 to

customer specification)

Coating credentials

Protecting this component using Corroglass will give

outstanding long term performance, with exceptional

resistance to solvent and sea water attack.

Corroglass is a high build glass flake vinyl ester resin.

The reducing piece will now meet the 15-year life

expectancy specified by the customer. This far exceeds

the capabilities of most other coated or uncoated

components used in such aggressive environments.

outstanding long term performance, with exceptional

resistance to solvent and sea water attack.

Corroglass is a high build glass flake vinyl ester resin.

The reducing piece will now meet the 15-year life

expectancy specified by the customer. This far exceeds

the capabilities of most other coated or uncoated

components used in such aggressive environments.

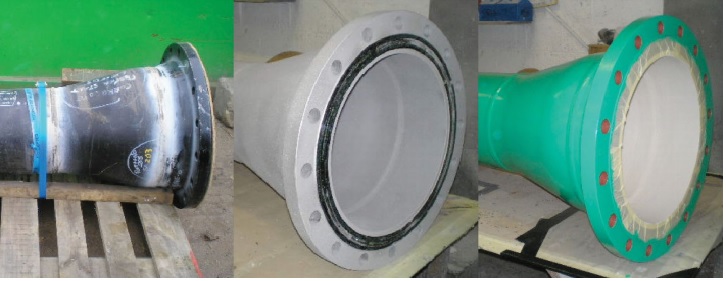

Photographs

Left: Reducing piece prior to coating work.

Middle: Reducing piece coated internally and externally.

Right: Reducing piece complete with top coat.

Middle: Reducing piece coated internally and externally.

Right: Reducing piece complete with top coat.