| 1-2: On arrival at works. 3: Internal corrosion. 3: Internal lining with Polyglass VEF. 4: Post abrasive blasting. |

| 5: First coat Polyglass VEF. 6: Top coat Fluiglide. 7: Internal lining. 8: Externals coated with Plasmet ZF and top coat of enamel. |

Protection from Seawater

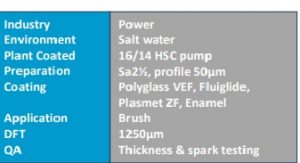

A 16/14 HSC pump was suffering severe internal corrosion due to salt water service and required refurbishment and ongoing corrosion protection. As well as protection against corrosion the client also wanted to achieve an increase in the pumps operating efficiency.

The internal surface was abrasive blasted to Sa2½ and thoroughly cleaned down to remove dust and debris. A first coat of Polyglass VEF was applied to a DFT of 800µm and when cured a top coat of Fluiglide friction reducing coating was applied to a final DFT of 1250µm.

Fluiglide

Fluiglide was developed to reduce fluid friction, thus improving flow and efficiency. Fluiglide ‘E’ can be used in conditions where light abrasion or solids are encountered.

Fluiglide also provides an effective corrosion barrier, preventing early fall-off in performance due to the formation of surface corrosion.

Protection and Efficiency Gains

The use of the Fluiglide system adds further efficiency increases over that gained by an engineering overhaul and refurbishment. As a result the pump operator will see significant energy cost reductions whilst operating. As a result the customer can expect a fast pay back of their initial investment. In order to provide all round protection the external surfaces of the pipes were coated with Plasmet ZF, a surface tolerant coating, before a final coat of enamel was applied.