US119: Neutralization Sump: Seminole Electric

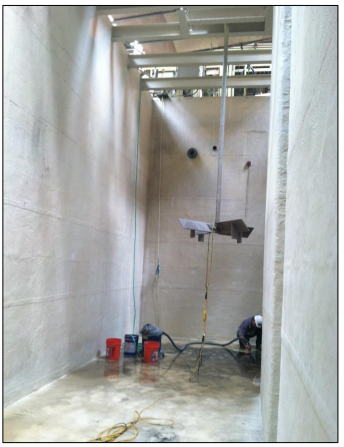

Neutralization tanks are common to most industrial plants as they facilitate a sump where the pH of plant water may be balanced by adding small amounts of 98% Sulfuric Acid (low pH) or small amounts of Sodium Hydroxide (high pH) to a body of water so as to reach a neutral pH (7). In this case at the coal fired power plant in Florida, rather than an above ground tank, the plant utilized the space beneath the acid and

caustic tanks by using a cast in place concrete sump as the plants neutralization sump.

At a neutral pH and up to about 10, the concrete is inert to the presence of the water. However, when immersed in low pH, concrete will begin to react the water and gradually break down; particularly where dosing of the acid / caustic occurs. For this reason, the customer lined the concrete with a thin film epoxy material years prior to this re-line.

Solution

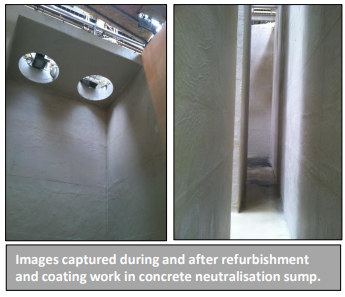

After completing abrasive blasting, large craters were evident (as much as 3 ft x 3 ft x 9 inches deep) on some of the side walls. These areas were primed with Plasmet ECP and the voids filled with Corrocoat Epoxy Polymer Concrete. The voids surrounding most of the steel beam supports were also filled with Epoxy Polymer Concrete, the beams, themselves were pre-coated with Polyglass VEF.

The next stage involved priming the entire sump using Polyglass WCP and thereafter lining the sump with Polyglass VEF, applied at 48 – 60 mils dft.

The project was completed in 2012 and eight years later, Corrocoat’s full-time, onsite team of coating applicators pass by the sump often and it still looks as good as new.

Quick Check Data