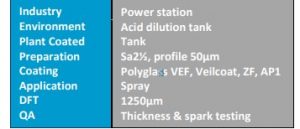

Protection for Acid Dilution Tank

An acid dilution tank in service at a UK power

station required protection against 15% sulphuric

acid at ambient temperatures averaging 77°F.

During the dilution process water enters the

bottom of the tank and acid is introduced more

slowly to the top of the tank.

The tank was blasted to Sa2½. It was then

thoroughly cleaned down and vacuumed. Polyglass

VEF was applied to the internals in several coats, to

reach the required DFT, followed by a coat of VE

Veilcoat. The externals of the vessel were coated

with Plasmet ZF and a top coat of Corrothane AP1

to the customer’s specified color.

Polyglass VEF is ideal for use in immersion

environments where superior chemical resistance

is required, making it the ideal coating for the acid

dilution tank.

After curing full QA tests, including thickness and

spark testing, were completed. No defects or

holidays were identified and the tank was assessed

as being fully protected for service in an aggressive

sulphuric acid service environment.

The Polyglass coating system will significantly

increase the expected service life of the tank and

will reduce periods of expensive downtime.