US116: Protection Against Sulfuric Acid

Two newly fabricated acid tanks for the water

treatment sector required protection before

entering service holding 96% sulfuric acid.

treatment sector required protection before

entering service holding 96% sulfuric acid.

D 7ft x H 12ft, 2ft Manway, 5 Nozzles

Plasmet AR3

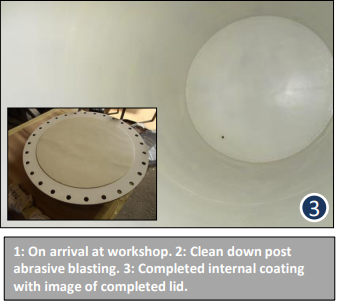

The acid tanks and lids were delivered to

Corroocoat’s workshop where they were abrasive

blasted to achieve the required cleanliness

standard before being thoroughly cleaned down

and vacuumed. Multiple coats of Plasmet AR3

was applied to reach the required DFT of 60mils.

AR3 was used as the coating as it provides

excellent resistance to sulphuric acid in immersed

environments at temperatures up to 120°F,

making it the ideal choice for this coating

specification. In between coats of AR3 wetted out

multiaxial glass fibre matting was applied to the

floor/wall interfaces to add increased structural

strength.

Corroocoat’s workshop where they were abrasive

blasted to achieve the required cleanliness

standard before being thoroughly cleaned down

and vacuumed. Multiple coats of Plasmet AR3

was applied to reach the required DFT of 60mils.

AR3 was used as the coating as it provides

excellent resistance to sulphuric acid in immersed

environments at temperatures up to 120°F,

making it the ideal choice for this coating

specification. In between coats of AR3 wetted out

multiaxial glass fibre matting was applied to the

floor/wall interfaces to add increased structural

strength.

After curing, thickness and spark testing was

carried out and final visual inspection made to

ensure the quality of the coating work completed.

The acid tanks were then prepared for dispatch to

the customer for installation, fully protected for a

significantly extended service life.

Quick Check Data