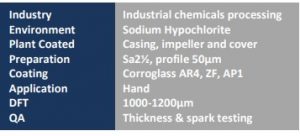

Protection in Base Alkali Conditions

A newly manufactured pump casing, impeller and

cover would be subject to service conditions of

sodium hypochlorite at a maximum concentration of

15%. To prolong the service life of the pump all

wetted internal surfaces required protective lining to

against base alkali solutions.

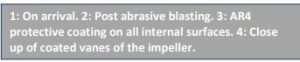

The pump casing was rebated to accommodate the

coating process, all areas not requiring coating were

masked and all parts abrasive blasted. A blow down,

sweep and vacuum followed to remove all dust.

Corroglass AR4, a specialist coating designed to give

best resistance in base environments, was applied in

multiple coats to achieve a DFT of 1000-1200µm.

The impeller was check balanced, pre and post

coating, on Corroserve’s Schenk dynamic balancing

machine to ensure it remained in the required

tolerance for final installation. Thickness and spark

testing was also completed to ensure no holidays

were present and to guarantee the quality of the

coating work completed.

Finally, the externals of the pump casing was coated

with Plasmet ZF a surface tolerant coating and a top

coat of Corrothane AP1. With complete corrosion

protection the pump could be expected to benefit

from an extended service life carrying an aggressive

alkali solution.