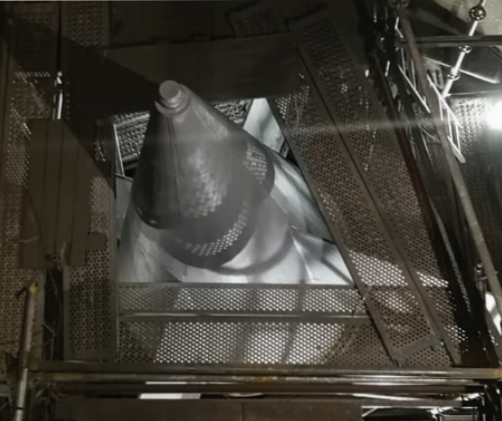

Corrosion & Abrasion ProtectIon for slag silo DiviDing Cones using rezorect

Last year, our team worked overtime to refurbish this 50% NaOH containment. The project utilized almost 3 cubic yards of our Epoxy Polymer Concrete (EPC) to fill pits and raise the grade of the containment from 3” on the high end down to 1/2” on low end. In order to apply so much EPC, we packaged the product in 1/5 Cubic Yard kits and mixed it in a 1/3 cubic yard concrete mixer.

The advantages of the EPC in this instance is the ability to apply the product in as thin as 1/2” think – whereas cementitious concrete would have required extensive demolitions or significantly increased thicknesses. Also, the EPC can be top-coated with one of our epoxy coatings immediately (rather than wait 30-60 days for the cement to finish hydration). We also applied a cross linking chemical resistant topcoat, Plasmet AR3.

We had the scaffolding removed from the 15′ diameter x 20′ tall waste solvent tank that we lined on site, allowing for this cool picture to be taken. The tank will be used onsite at a petrochemical plant to house waste Xylene and Toluene from the site. As per the chemistry heuristic, “like dissolves like”, most epoxy systems would not do well in this environment so acceptane of the specification and turnkey application of our Polyglass VEF glass flake reinforced vinyl ester lining system was the obvious choice.

Polyglass VEF was specified at 48 mils dft plus a Polyglass VE Veilcoat at 12 mils nominal. The product is for sale to interested civil, flooring and coating contractors in the US and Canada. Our turnkey services may be available in Florida, Georgia and South Carolina.