Blog

100 operatives…. 50 vessels…. 3 Weeks… 24/7? no Problem!

During september and october 2019 Corrocoat Caspian was appointed by KPo (Karachaganak Petroleum operating b.v.) as a key contractor for the lining of process vessels during a shutdown event which happens only once every five years. KPO b.v. is a consortium of international oil companies Royal Dutch Shell, Eni, Chevron, LUKOIL and KazMunaiGas who are developing the huge Karachaganak gas condensate field – one of the world’s largest. Located in northwest Kazakhstan it covers an area of over 280 square kilometres and holds an estimated gross reserve of over 2.4...

Corrocoat sel

Corrocoat SEL is a spray applied epoxy glassflake lining, intended for single or multi-coat application, that provides durable chemical protection in aggressive atmospheric conditions and immersed environments. Corrocoat SEL has a smooth finish and can withstand immersed temperature levels up to 90°C in oil, and non-immersed levels up to 100°C. It displays excellent resistance to discolouration that can occur on exposure to strong concentrations of acid. SEL has excellent application characteristics and edge coverage in single coats and is predominately applied...

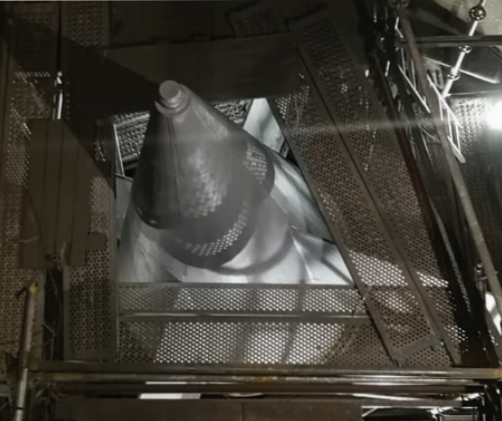

Corrosion & Abrasion ProtectIon for slag silo DiviDing Cones using rezorect

the dividing cones inside a slag residue silo, manufactured from hardox 500 steel, were subject to a constant abrasive environment. the client required a solution that would prolong the overall expected service life of the steel cone structures by applying a protective, abrasion-resistant coating over the steel structure. Corrotech recommended using a trowel applied abrasion-resistant compound – Rezorect 125 Ceramic Wearing Compound, from the Rezorect family of engineering emergency repair products. Rezorect 125 was specially developed to protect against...

CorrocoAt ZIP e Beats off the CompetItIon

the coast of India is home to a number of large petrochemical and power industries. Kirloskar Corrocoat Private limited has a proven and reliable track record in internal and external pipe coating to protect against the saline atmosphere found at the coast and against soil corrosion of underground pipelines. In an expansion project, one of India’s leading crude refining and petro chemical companies required corrosion protection for stainless steel pipes which were to be buried in the coastal belt in chemically aggressive soils. The pipes would require a proven...

Everything’s ship-shape at Corrocoat hellas

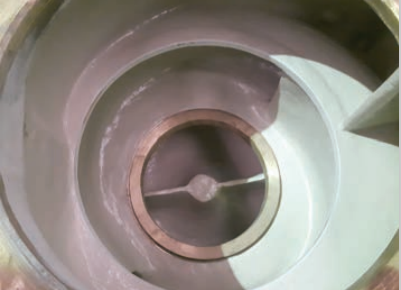

A bronze main engine sea water pump was considered as fit only for scrap. the shipping company was ready to replace it with a new pump until they contacted Corrocoat hellas. messages were exchanged between the company and the ship’s Chief engineer who forwarded images from the vessel to see if a repair was possible. Corrocoat hellas was able to inform him that this kind of work is a routine job for them. he was told that he could send the pump to their workshop for a full inspection and evaluation of the repair work required. After a full and detailed...

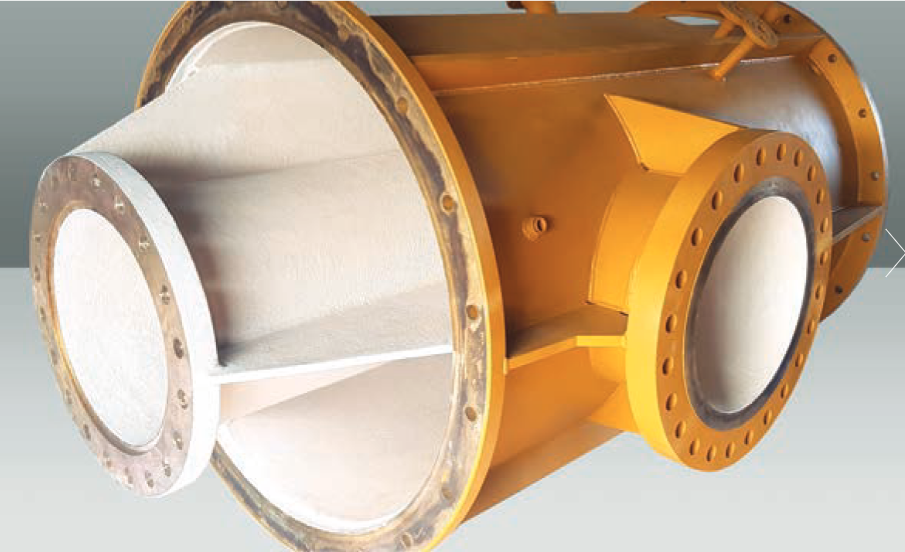

long term Protection for seawater Pump Discharge head

Uni-Arab engineering and oilfield services in the united Arab emirates were approached by a contractor, Pilco, on behalf of their client Adnoc offshore, to internally line a seawater booster pump discharge head. the newly fabricated discharge head would be subject to constant corrosive seawater service and the client wanted to ensure it was fully protected in order to extend its service life. It was delivered to Uni-Arabs workshops, having been abrasive blast cleaned by the contractor, where a full inspection was completed. The surface profile was found to be in...

A Royal Day Out – Naming of the RRS Sir David Attenborough

The RRS Sir David Attenborough, built byCammell Laird for the British Antarctic Survey, is one of the world’s most advanced polar research vessels. Corroserve was asked to provide corrosion protection against seawater for a large number of seawater pipes due to be installed on the ship. The pipespools and slip on flanges were delivered to the company’s Leeds workshopswhere after suitable preparation Corroglass600 was applied in multiple coats, using theAgmec internal pipe spaying method, to achieve the desired level of corrosion protection. As a supplier to the...

Recent Comments